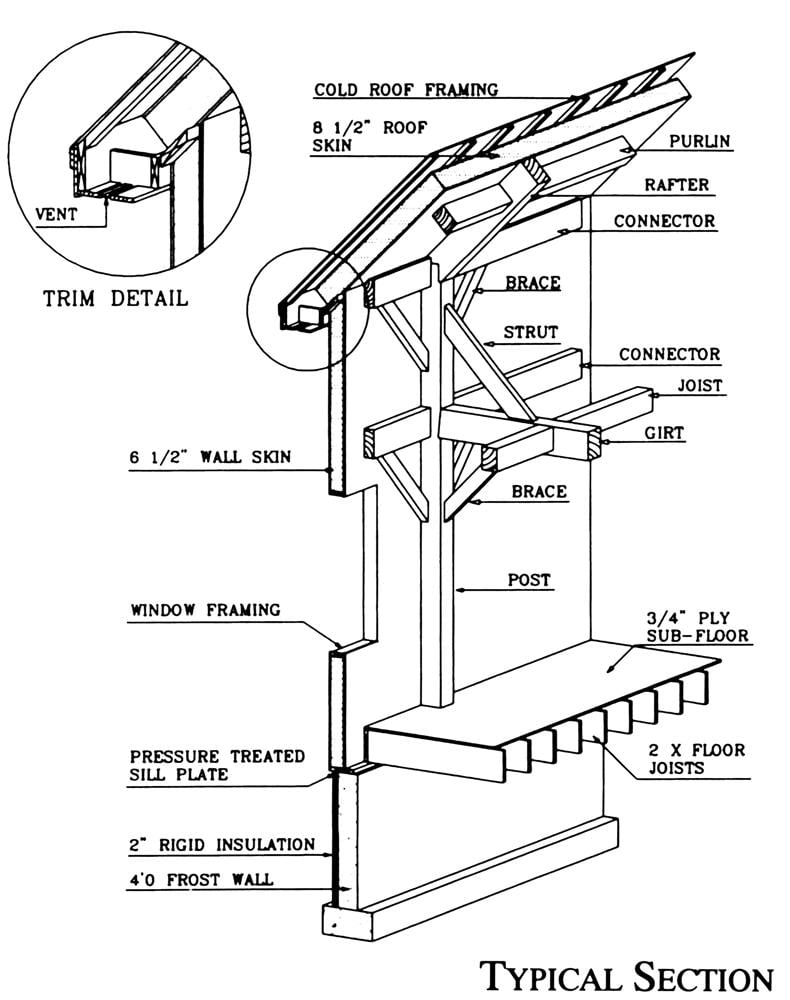

Stressed skin design has generally been applied primarily to roofs or walls with a single skin of sheeting directly fixed to the purlins side rails or beams by for example self drilling self tapping screws or fired pins.

Stressed skin floor system.

A with top skins only 1 2 5 8 or 3 4 in thick and b with both a top skin and a 1 4 in plywood bottom skin keywords.

Stressed skin deck panels.

Richmond olympic oval wood wave roof.

This is due to the integral engagement of the floor panel that is the stressed skin to the web and the critical slip.

Our deck panels are designed for a standard load rating of 125 lbs sq.

This system in theory is one of.

Projects that use stressed skin panels.

In the early 1930 s the u s.

Vandusen botanical gardens visitor centre.

Particularly those between the web and skin as well as in between the web and the bottom flange.

Thompson river university law school wood roof.

The most efficient structural systems for walls floors ceilings or roofs.

Adhesives incorporated into the stressed skin flooring system play a highly critical role in the ultimate capacity and behaviour.

Even if you don t have an actual skin condition dealing with way more stress than usual for a significant amount of time might make your immune system hyperirritable so something that doesn.

A stressed skin panel is an insulated building panel that is comprised of a foam core sandwiched between two skins the core made from polyurethane or styrene foam is both durable and light weight.

However many modern roof systems involve two metal skins with insulation positioned between them and this affects their in plane resistance.

In mechanical engineering stressed skin is a type of rigid construction intermediate between monocoque and a rigid frame with a non loaded covering.

Common sizes are 5 x 5 and 4 x 8 chosen to keep the deck panels light so they are easy handled up on the structure without compromising strength.

Its many advantages have made it extremely popular with the pre.

A stressed skin structure has its compression taking elements localized and its tension taking elements distributed typically the main frame has rectangular structure and is triangulated by the covering.