Abstract to predict the nonlinear stress strain behavior and the rupture strength of orthotropic ceramic matrix composites cmcs under macroscopic plane stress a concise damage based mechanical t.

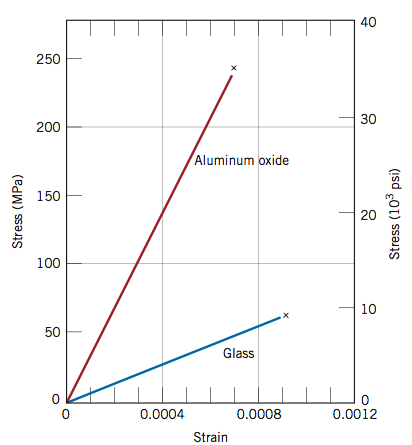

Stress strain diagram for ceramics.

This curve helps in the analysis of.

How to draw stress strain curve or diagram.

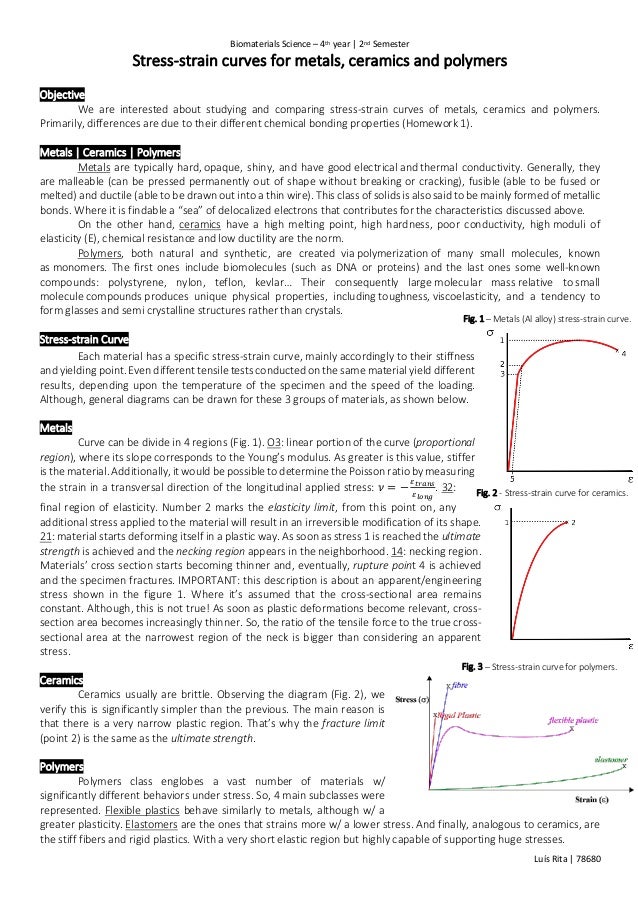

1 metals al alloy stress strain curve.

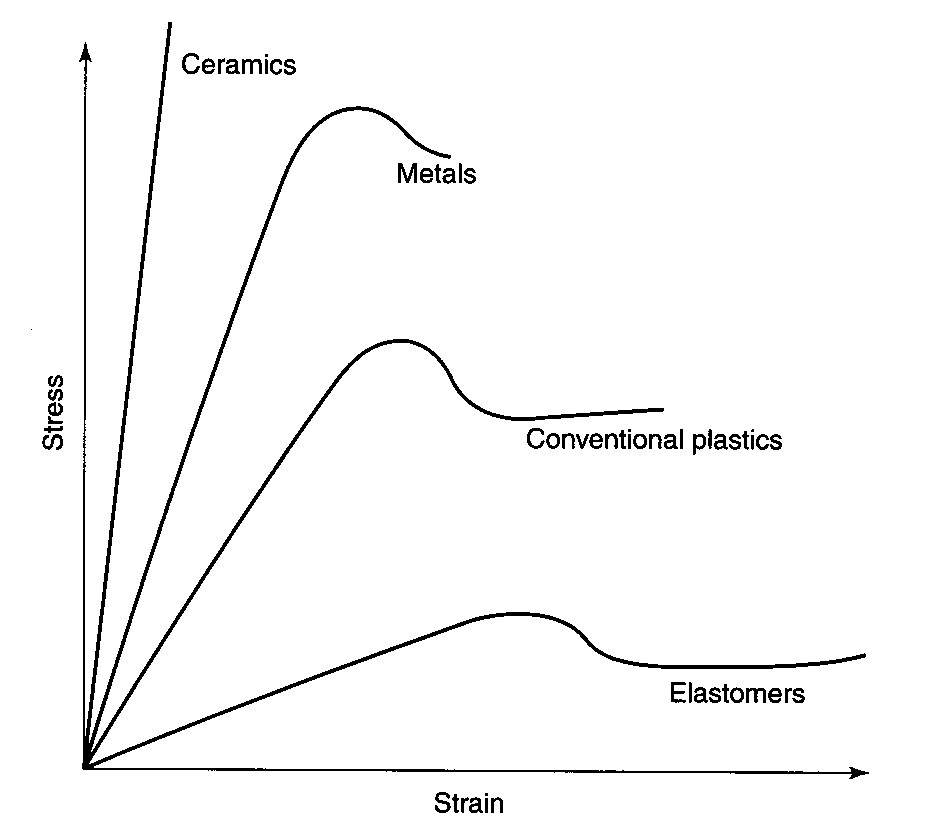

Elastomers are the ones that strains more w a lower stress.

Knowing the original cross sectional area and length of the specimen the normal stress σ and the strain ε can be obtained.

It may vary due to the temperature and loading condition of the material.

The electric strain gauge was used to study the deformation of several types of ceramic materials under stress.

The diagram shown.

For brittle ceramics a three point bending apparatus shown in the figure below is used determine the stress strain behavior and the measurement results are used to calculate an equivalent modulus of elasticity.

Jacers is a leading source for top quality basic science research and modeling spanning the diverse field of ceramic and glass materials science.

With a very short elastic region but highly capable of supporting huge stresses.

In crs tests and cgts the average strain e ah h or the void ratio e can be related to an average effective stress calculated with the fol lowing equation u a uuo a u u 6 where u is the total vertical applied stress u.

A tensile test is done on the material for drawing the stress strain curve.

And finally analogous to ceramics are the stiff fibers and rigid plastics.

Stress strain curve for brittle and ductile material stress strain curves are very essential tool to analyze the properties and performance of a material.

With the sample geometry a stress strain curve can then be generated from the recorded load and displacement.

7 18 callister rethwisch.

2 stress strain curve for ceramics.

The hard fired materials exhibit straight line deformation to failure while the softer fired have a proportional elastic limit beyond which the stress strain curve deviates.

A typical stress strain profile for a ductile metal resembles the following.

The graph of these quantities with the stress σ along the y axis and the strain ε along the x axis is called the stress strain diagram.

It was found that they behaved as elastic materials.

In engineering and materials science a stress strain curve for a material gives the relationship between stress and strain it is obtained by gradually applying load to a test coupon and measuring the deformation from which the stress and strain can be determined see tensile testing these curves reveal many of the properties of a material such as the young s modulus the yield strength.

The stress strain diagram for different material is different.

1 2 typical stress strain curve of a ductile metal2 the material initially behaves in a linear elastic manner.

The curve has the information of tensile strength yield point breaking point etc.

The stress strain diagram differs in form for various materials.

In the tensile test a curve is drawn between the stress and strain.

Stress and strain are linearly related and.